More about Miyoshikiku

In doing some research about this great brewer I stumbled across a great article written by some brewers who went to Mamiya san's place and helped brew for a few days.

It has info re the yeast that he uses and the techniques he employs. Also re what he is trying to do. Make sake that is not like sake.

Please enjoy the article.

Sake making at Miyoshikiku in Tokushima

Joined by 13 sake enthusiasts from everywhere...!

This is the story about the great experience we had at Miyoshikiku sake brewery in Tokushima.

Sake plays an essential role in Japanese culture. You might have seen sake barrels at famous shrines like Meiji Shrine. Sake is still used for ceremonial purposes at temples and shrines but it is sadly a diminishing industry.

(You can see a YouTube video showing sake barrels at Meiji shrine here.)

During the COVID pandemic, almost 150 breweries went out of business. I run a company called Sake Lovers Inc where we support small craft breweries and run sake brewery tours. This year, we organized a sake-making experience at one of the struggling sake breweries in Tokushima.

Miyoshikiku sake brewery was founded in 1903. What makes the brewery unique is that the president and the toji (head brewer), Ryoichiro Mamiya, is a lover of rock-n-roll. He loves punk rock and plays guitar in a local band. One of his 3 daughters plays drums during school days.

The brewery was joined by the first and only female toji in Shikoku, Ikuko Udaka, who previously worked at Ehime prefecture’s sake brewery (which went out of business in 2009).

Miyoshikiku strives to bring changes to the sake industry. Utada-san makes Yamahai sake there. Miyoshikiku is currently creating ambient yeast (Kuratsuki Kobo, ambient wild yeast) and is now in the process of registering and naming it. Also, their sake making is different from other sake breweries.

Here are some of the things Mamiya-san told me about his style of sake brewing:

“Many customers think that Miyoshikiku is characterized by its sweetness, but in fact, we are aiming for something a little different. What we are aiming for is the harmony and balance of water, alcohol, and flavor components. Striving to make our sake drunk without tasting much alcohol, more suited to be modern palate.”

“The first element we considered in terms of differentiating our sake from the others was the yeast we cultivated called Tokushima yeast. This yeast produces a rich floral aroma that stands out in the mouth. But even though the aroma is very rich and sweet, it would be no good if it lacks balance with the taste, so the taste must be as good as the aroma.

“Next, I considered the koji production and what to do. The overall process of koji making is the complete opposite of conventional ginjo brewing.

Because Tokushima yeast is generally a weak yeast, it is brewed at an extremely high temperature. The soe-koji and naka-koji are so-haze koji (total round koji — you can read more about koji here) so that the rice will dissolve completely. Tome is also done at a relatively high temperature. (The koji rice is used in 3 stages — soe, naka and tome.)

“Tokushima yeast is originally a small acidic yeast. A veteran brewer can produce delicious sake with it with an acidity level of 0.8 or so. So, when the temperature rises, the koji rice gets dissolved, and the acidity rises. Trying to bring up the acidity level with yeast that does not produce much acidity will produce more malic acid and other acids than lactic acid, which is common in conventional sake. That is the characteristic of the ‘Miyoshikiku’ brewing process.

“The other important point is to not extend the fermentation period of moromi If we try to stretch it to 30 days, we will get a flavor and aroma that we don’t want, so we try to create an environment that allows us to complete the process within 25 days. This is the same for both 60% junmai sake and 40% daiginjo.

“Once we have decided on the brewing, we do not add water to the mash. We also do not mix tanks. I believe it is my job to create an environment that allows good fermentation to take place because it is the yeast that brews the sake.”

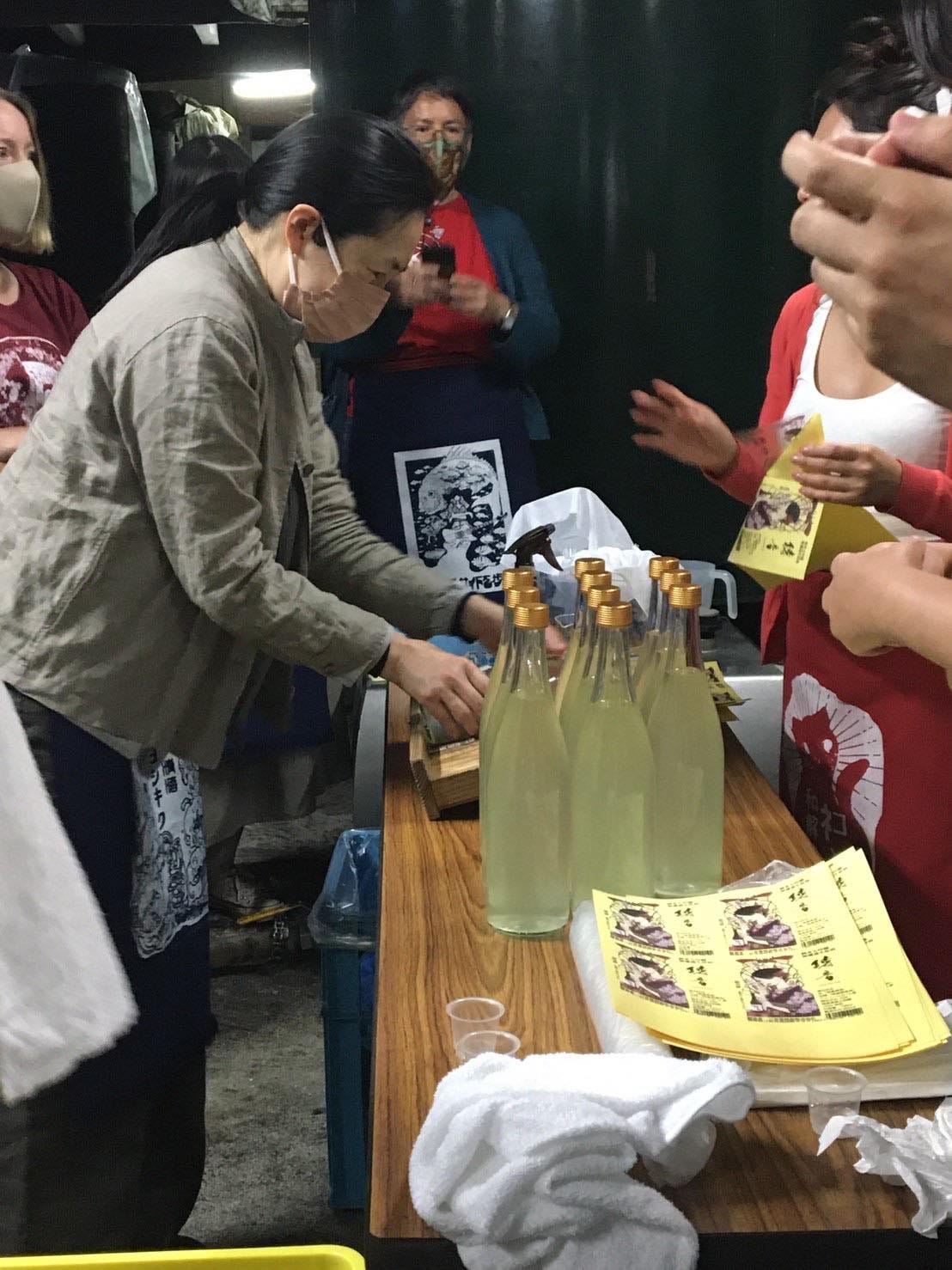

Not just the sake brewing style differed from most other sake breweries, the labels on the bottles are also quite different. Look at these cute labels.

Some critics bash them by saying that they are using cute labels since they aren’t confident in their sake. That is not true. The brewery has 30 products or more, which is quite a lot for a small brewery like Miyosikiku. His daughters say that every time they go back home, they find something they haven’t seen before.

We were able to experience steaming the rice, cooling the rice, koji rice making for 2 days, bottling sake, hand labeling sake bottles, and removing sake lees.

For those of you who don’t know what sake kasu is (sake lees or sake cake) please read the article I wrote about sake kasu in the Japanese Food Guide.

You can read the article here.